CNC Machining

CNC Machining

This assignment

is to make something big! I knew I wanted to design it entirely on the computer

from scratch. Sculptris gave me a great first step.

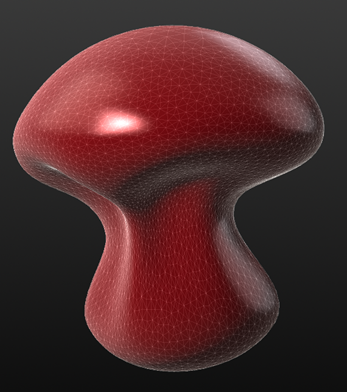

Starting off with a sphere, I pinched and poked until I had a convincing fungi

The OBJ file was flattened and sliced on the

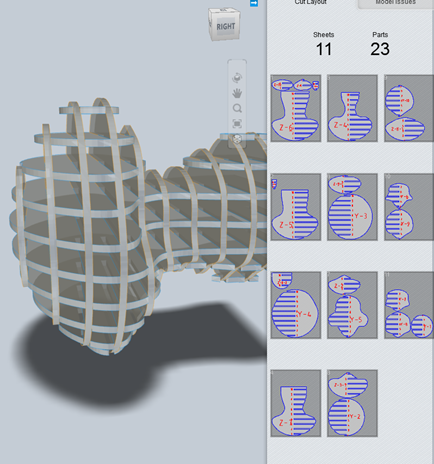

bottom, using Netfab, then brought into 123Dmake.

This program is awesome! The interface wasn't crowded with icons, and simple

enough to  explore. I was successful at

creating a file ready for the shopbot

& I was overjoyed at how simple it is! I then scaled my mushroom down to

1/8 inch birch

explore. I was successful at

creating a file ready for the shopbot

& I was overjoyed at how simple it is! I then scaled my mushroom down to

1/8 inch birch  wood, and lasered a mini version of the finished product so I could

see it right away. Later on, I got to use the shop bot to make a large one, and

things went very smoothly. The CNC machine is very capable at cutting many

types of material, for this project I went for 3/4 inch MDF 8X4 foot board, as I had

heard it was easiest to fit together. The vaccuumm on the bed holds the board down while the 3/8 inch bit drills holes where all the corners and tight places will be. After this precaution, we switched bits to 1/2 inch, and set the feed rate to 200, spindle speed 18k. The bit drills out most of the top layer, leaving a very thin line of board left. This is important to do because otherwise the pieces may be caught and flung off the bed, at the very least, shift the shape so it is cut incorrectlty. After the pieces were cut out, I followed the intsructions made by 123D Make, to fit everything together. It's important to note with this material that it is imperative to sand the edges really well before the pieces will fit neatly!

wood, and lasered a mini version of the finished product so I could

see it right away. Later on, I got to use the shop bot to make a large one, and

things went very smoothly. The CNC machine is very capable at cutting many

types of material, for this project I went for 3/4 inch MDF 8X4 foot board, as I had

heard it was easiest to fit together. The vaccuumm on the bed holds the board down while the 3/8 inch bit drills holes where all the corners and tight places will be. After this precaution, we switched bits to 1/2 inch, and set the feed rate to 200, spindle speed 18k. The bit drills out most of the top layer, leaving a very thin line of board left. This is important to do because otherwise the pieces may be caught and flung off the bed, at the very least, shift the shape so it is cut incorrectlty. After the pieces were cut out, I followed the intsructions made by 123D Make, to fit everything together. It's important to note with this material that it is imperative to sand the edges really well before the pieces will fit neatly!